China Manufacture H500 Series High Performance Vector Variable Frequency Inverter/AC Drive / VFD/Power Inverter 160kw 380V

Product Description: H500 series universal frequency converter is a kind of high quality product created by H-WISE in or

Description

Basic Info.

| Model NO. | H500-0160T4GB |

| Link of Transformation | AC-DC-AC Variable-Frequency Drive |

| Function | Simple Type, Elevator Special, Textile Special |

| Certificate | ISO9001, CE |

| Control Modes | Open Vector Control(SVC), V/F Control |

| Lead Time | 7-10 Working Days |

| Wanrranty | 2years |

| Input Frequency | 50/60Hz |

| Input Voltage | Three Phase, 380V |

| Color | Black |

| Transport Package | Carton/Wooden Box |

| Specification | 785*385*305mm |

| Trademark | H-WISE |

| Origin | Zhejiang, China |

| HS Code | 8504409999 |

| Production Capacity | 100000per/Year |

Product Description

Product Description:H500 series universal frequency converter is a kind of high quality product created by H-WISE in order to meet the needs of the industry market and users.

Its performance and function are highly integrated, and it has an adaptive voltage vector algorithm. It can output ideal sinusoidal waveform in various frequency

segments to ensure the reliable operation of the motor.Easy to operate, optional Rs485 communication interface, CAN communication interface, PG interface.

Support Modbus bus.

Power class: 380V 3PH, 0.75-400KW

Name plate:

Product Features:

H500 Series Model:

H500 Series Techinical Standard:

| Item | Specifications | ||

| Basic functions | Control system | Current Vector General Purpose Inverter. | |

| Compatible motor | Induction motors. | ||

| Maximum frequency | Vector control: 0~500Hz; V/F control: 0~3200Hz. | ||

| Carrier frequency | 0.8kHz~12kHz; Depending on load, can automatically adjust. | ||

| Input resolution | Digital: 0.01Hz; Analog: maximum frequency×0.1%. | ||

| Control modes | Open vector control (SVC); Closed loop vector control (FVC); V/F (scalar) control. | ||

| Starting torque | G type: 0.5Hz/150% (SVC); 0Hz/180% (FVC). P type: 0.5Hz/100%. | ||

| Speed range | 1: 100 (SVC) | 1: 1000 (FVC) | |

| Speed accuracy | ±0.5% (SVC) | ±0.02% (FVC) | |

| Torque accuracy | ±5% (FVC) | ||

| Overload capacity | G type: 150% rated current 60s; 180% rated current 3s; P type: 120% rated current 60s; 150% rated current 3s. | ||

| Torque boost | Automatic | Manual 0.1%~30.0% | |

| V/F curve | Straight-line V/F curve Multi-point V/F curve N-power V/F curve (2-power, 1.4-power, 1.6-power, 1.8-power, 2-power square) | ||

| V/F separation | Two types: complete separation; half separation. AVR output. | ||

| Ramp mode | Straight-line rampS-curve rampFour groups of acceleration/deceleration time: 0.0-6500.0s | ||

| DC braking | DC braking frequency: 0.00 Hz to maximum frequency Braking time: 0.0-36.0s Braking action current value: 0.0%-100.0% | ||

| JOG control | JOG frequency range: 0.00-50.00 Hz JOG acceleration/deceleration time: 0.0-6500.0s | ||

| Simple PLC | Up to 16 speeds via the simple PLC function or DI terminals | ||

| Onboard PID | Process-controlled closed loop control system | ||

| Auto voltage regulation (AVR) | Keep constant output voltage automatically when grid voltage fluctuates. | ||

| Overvoltage/Overcurrent stall control | The current and voltage are limited automatically during the running process so as to avoid frequent tripping due to overvoltage/overcurrent. | ||

| Fast current limit function | Protect inverter from overcurrent malfunctions. | ||

| Torque limit and control | It can limit the torque automatically and prevent frequent over current tripping during the running process. Torque control can be implemented in the FVC mode. | ||

| Stop for a second | When the instantaneous outage occurs, the voltage is compensated by the load feedback energy to keep the converter running for a short time. | ||

| Personalization features | Fast flow restriction | Avoiding Frequent Overcurrent Faults in Inverters | |

| Timing control | Time range: 0.0-6500.0 minutes | ||

| Two-motor switchover | Two motors can be switched over via two groups of motor parameters. | ||

| Fieldbuses | RS485, Profibus-DP, CANlink, CANopen (extension cards needed) | ||

| Powerful background software | Supports frequency converter parameter operation and virtual oscilloscope function. Graphic monitoring of internal state of frequency converter can be realized by virtual oscilloscope | ||

| Operations | Command source | KeyboardControl terminalsSerial communication portYou can perform switchover between these sources in various ways. | |

| Frequency source | 11 frequency sources, such as digital setting, analog voltage setting, analog current setting, pulse setting and serial communication port setting. You can perform switchover between these sources in various ways. | ||

| Auxiliary frequency source | 11 auxiliary frequency sources. It can implement fine tuning of auxiliary frequency and frequency synthesis. | ||

| Input terminal | 6 digital input (DI) terminals (DI5 supports up to 100 kHz high-speed pulse input) 3 analog input (AI) terminals which support 0-10 V voltage input or 0-20 mA current input | ||

| Output terminal | 2 digital output (DO) terminals (FM supports 0-10 kHz square wave signal output) 1 relay output terminal 2 analog output (AO) terminals which support 0-20 mA current output or 0-10 V voltage. | ||

| Display and panel | LED display | Displays parameters. | |

| Key lock | It can lock the keys partially or completely and define the function range of some keys so as to prevent misconducts. | ||

| Protection functions | Motor short-circuit detection at power-on, input/output phase loss protection, overcurrent protection, overvoltage protection, under voltage protection, overheat protection and overload protection. | ||

| Optional parts | PG card, brake unit, RS485 card, CAN card, Profibus-DP card. | ||

| Environment | Location | Indoor, free from direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip or salt. | |

| Altitude | Less than 1000m. | ||

| Ambient temperature | -10°C to +40°C (de-rated if the ambient temperature is between 40°C and 50°C) | ||

| Humidity | Less than 95%RH, without condensing | ||

| Vibration | Less than 5.9m/s2 (0.6g). | ||

| Storage temperature | -20ºC~+60ºC. | ||

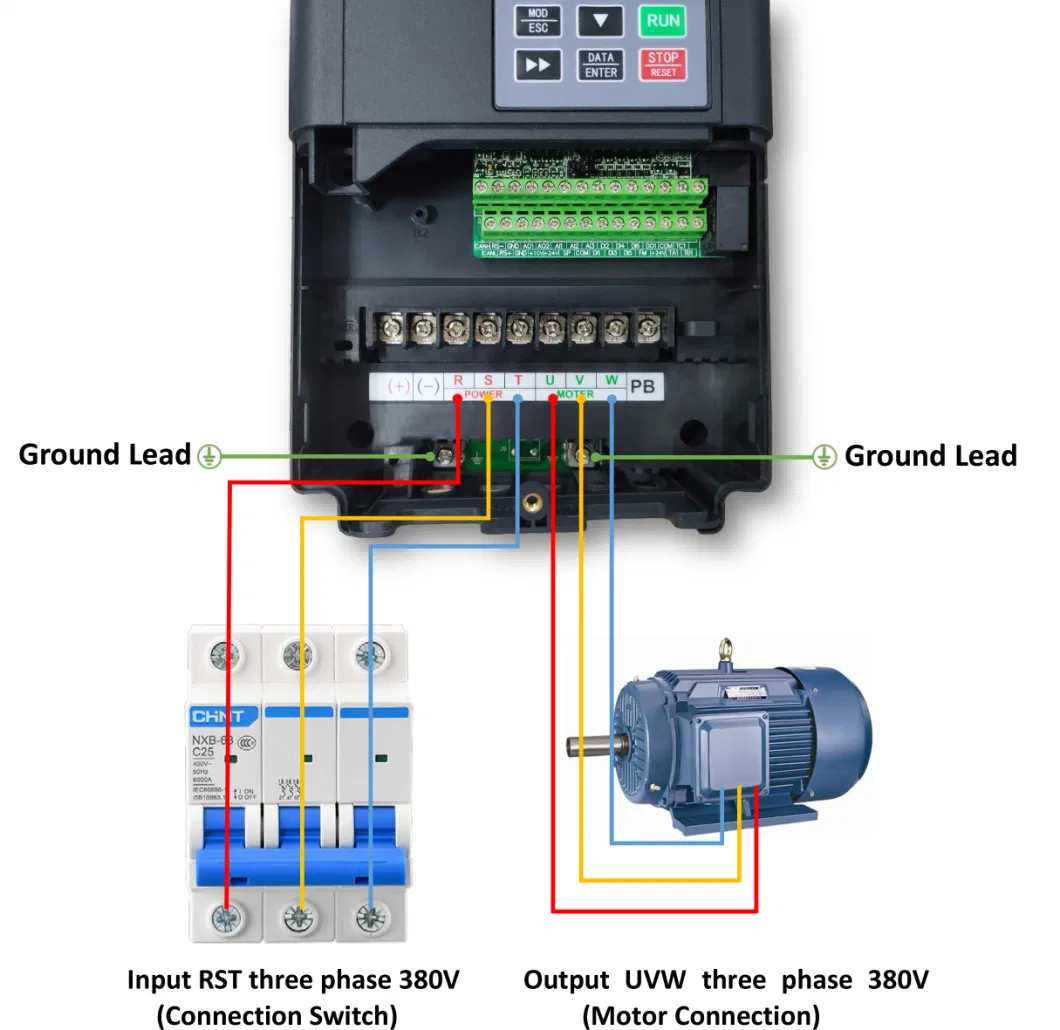

Standard wiring diagram:

2.2-22KW

30-160KW:

Scope of application:

H500 series inverter is widely used in machine tool, processing center spindle, elevator, elevator, textile machinery, plastic machinery, printing and packaging machinery, fan and water pump,air conditioning compressor and other fields, for the majority of customers to create a good user experience.

Application online images:

DIMENSION:(UNIT:MM)

| Inverter model | Dimensions(mm) | Holes(mm) | Net(Kg) | |||||

| W1 | H1 | H | W | D | D1 | |||

| H500-0160T4GB | 240 | 760 | 785 | 385 | 305 | 295 | φ8 | 58.7 |

Factory outline:

FAQ :

1,Can I get some samples?Yes, Sample order is available for quality check and market test .Sample product,buy one set product (1.5KW or 2.2KW)and get free one set product(0.4KW or 0,75KW).2,What's delivery time?It usually takes 7-10 working days.3,What's your warranty terms?We offer 2 years warranty time.4,Can the inverter connect with computer?Yes, all inverters have built-in RS485 port and support Modbus communication protocol. 5,How does your factory do the quality control?Quality is priority ,we always attach the importance to quality control from the beginning to the end of the production .Every product will be fully assembled and carefully tested before packing and shipping .6,Do you have the products in stock?Depends on your request, we have standard models in stock. Some special products and big order will be newly produced according to your order.7,Can you sell spare parts?

If you are using H-WISE products .we can sell spare parts to you.

8,How can I trust you?Our company's values are integrity, responsibility, innovation and cooperation and our company has been audited and approved CE, ISO9001. Assessment report could be sent to you by e-mail. Also we are the made-in-China's Premium member supplier.

Prev: Economical General Purpose Variable Frequency Inverter

Next: Gk500 Mini Frequency Inverter for General Purpose Applications

Our Contact

Send now